Battery & Power

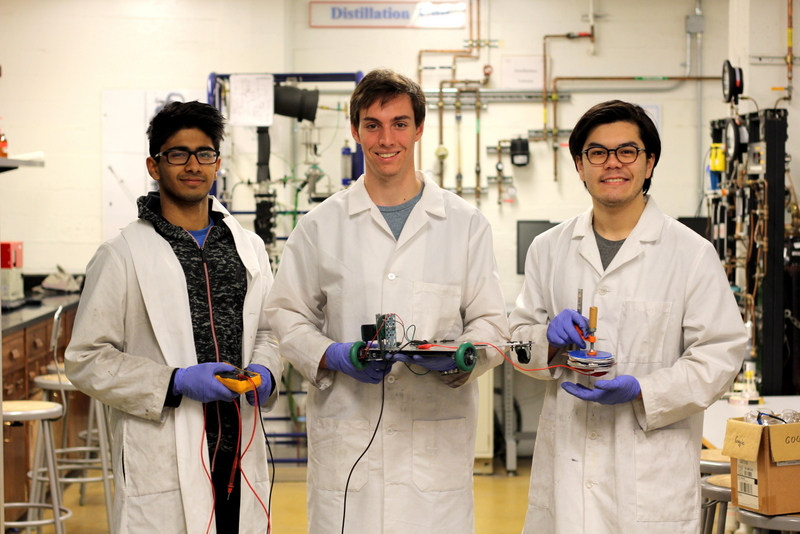

Aluminum Air Battery

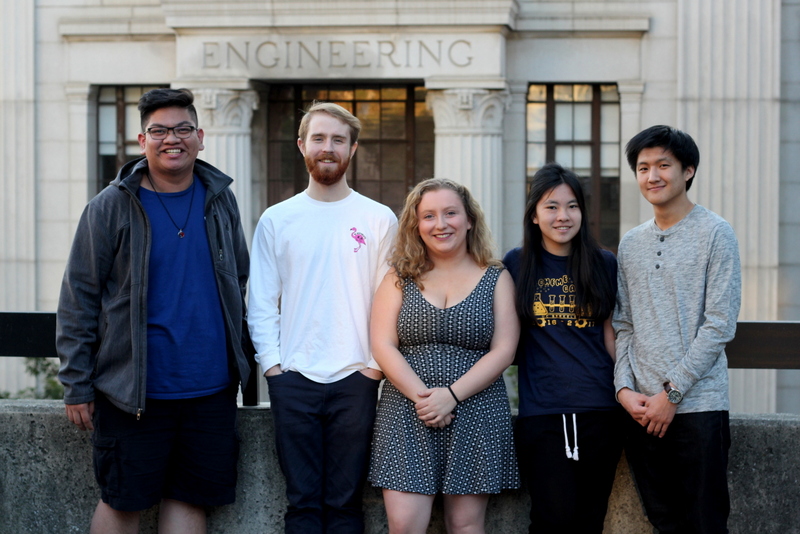

PROJECT LEAD: McGregor Stadtmiller

TEAM: Sreyas Narayanan, McGregor Stadtmiller, Stephen Bagley, Matthew Helle (not pictured)

Our team is focused on providing power for the car through use of an aluminum air battery. Never having been used before by the Berkeley Chem-E car team, this project is focused on developing a battery that provides enough power to run the car, and to get the power output as consistent as possible. We test additives, structural changes and side reactions to optimize our power output and to get the power source competition ready.

Biofuel Internal Combustion Engine

PROJECT LEAD: Jonathan Ngan

TEAM: Walter Piszker, Edward Shin, Laura Strong, Winston Ou, Jonathan Ngan

Our team will power the car through a biofuel internal combustion engine (ICE). Some main points of interests will be in synthesis of compatible biofuel, as most ICE's at a small scale (model) operate differently than traditional car ICE's, leading to increased difficulty in incorporating modern biofuel mixtures. We will be testing different additives, different mixtures, engine filters, and, possibly, engines with different strokes and ignition mechanisms.

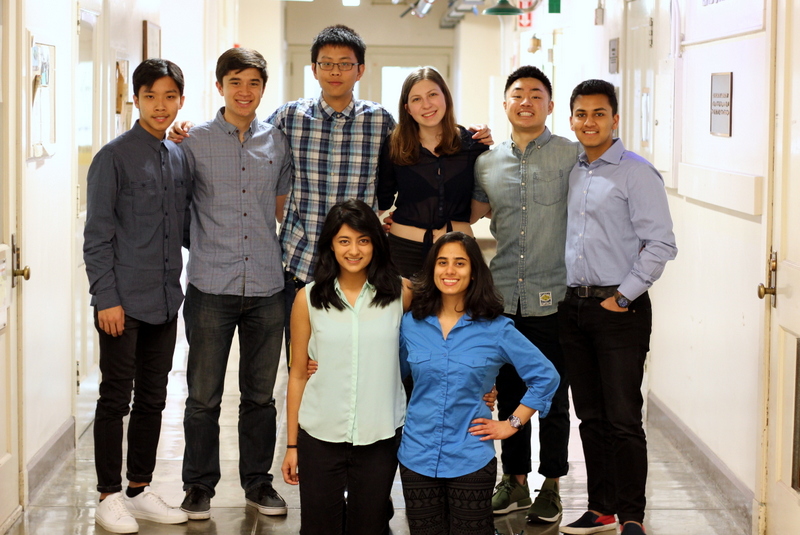

Experimental Battery

PROJECT LEADS: Rajashree Bhattacharya & Sanya Sehgal

TEAM: (back row) Kelvin Ye, Ethan Woodbury, Ryan Yao, Annie Preece-Scaringe, Alan Wu, Vedant Kedia; (front row) Rajashree Bhattacharya, Sanya Sehgal

Our team is experimental, meaning we explore and design power sources that the Berkeley team hasn't tried or had success with before. Our project involves thermoelectric power generation. Thermoelectric generators generate power from hot/cold temperature differences. This semester we are focusing on finding the best gas evolution or heat generating reactions that are both safe and fast for the two teams, as well as build the generator itself. This is a brand new team, and we need people with initiative and interest in research and development. If you are excited about the opportunity to help shape and design these systems with your own ideas, join us!

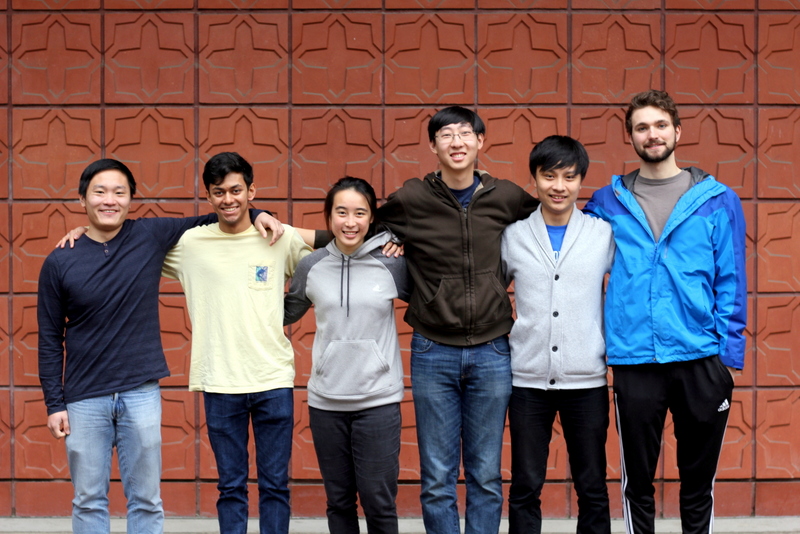

Hydrogen Fuel Cell

PROJECT LEAD: Murali Subramanian

TEAM: (back row) Vishakh Pillai, Vishnu Dharmaraj, Alec Glisman, Vaikunth Balaji; (front row) Murali Subramanian, Alan Liu, Aaron Flores

The really cool thing about the Hydrogen Fuel Cell is that it runs just on Hydrogen gas - because we can get the oxygen required for the reaction from air. Hydrogen gas is sent through one plate and air (which contains oxygen) is sent through the other. Hydrogen is oxidized at the anode, while oxygen is reduced at the cathode. This produces a potential difference which is used to power the circuit and in turn the car.

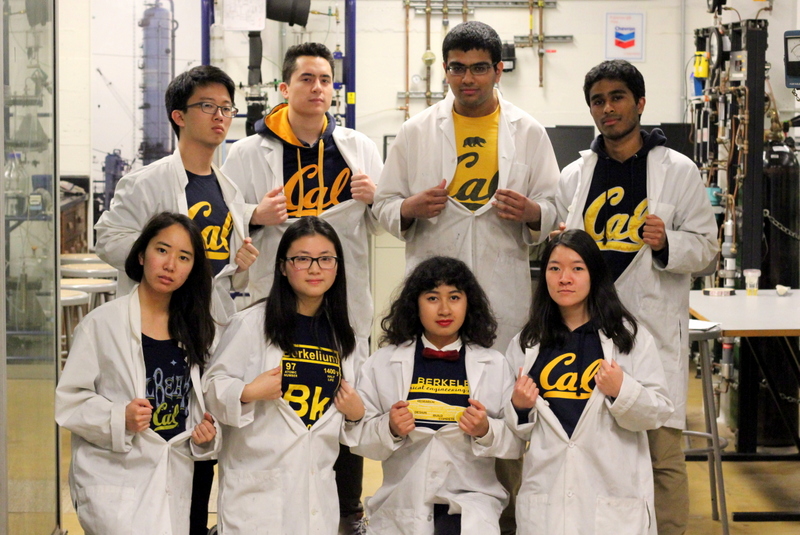

Zinc Air Battery

PROJECT LEAD: Sophia Chan

TEAM: (back row) Taehun Kim, Chris Ching, Parth Patel, David Koshy, (front row) Sophia Chan, Helen Yan, Roxana Martinez, Ashley Yin

The zinc-air battery uses a zinc anode, a graphite-based cathode, and potassium hydroxide for the electrolyte. Each cell will also use filter paper as a separator and copper for a current collector. Our plan is to spend a short amount of time testing different aspects of the anode, cathode, and electrolyte, before optimizing the size and weight of the battery packs.

Control

Chemiluminescence Clock

PROJECT LEADS: Emmy Tian & Sharon Tian

TEAM: (back row) Herman Bathla, Richard Sim, Ming Ye, Aneesh Akella, (front row) Moriel Dror, Grace Li, Emmy Tian, Sharon Tian, Irene Kim (not pictured)

Luminol is a chemical commonly used in forensics analysis to identify blood. When mixed with an oxidizing reagent, luminol emits a blue glow of light, which can be detected by a photosensor, causing a break in a circuit and turning off the motor. A demo of the luminol reaction can be found here.

Enzymatic Clock

PROJECT LEAD: Godwin Liang

TEAM: Songhao Li, Aayush Patel, Annie Wu, Jiangao Fang, Godwin Liang, Jack Melcher

The goal of the Enzymatic Clock team this semester is to finish developing the stopping mechanism for the car and have it ready for competition. The clock design is mainly based on using information about chemical catalysts and reaction rates to be able to control how long the car runs for. In the reaction flask, the decomposition of hydrogen peroxide into gas is catalyzed by the extracted catalase. This helps operate the photosensor-based control box that will ultimately stop the car. We will focus on continuing to improve our catalase purification technique and finalizing the calibration curve for the clock. If you have any questions about the project, feel free to shoot me a message on Facebook or e-mail me godwinliang@berkeley.edu.

Electrical

PROJECT LEAD: Stephan Kaminsky

TEAM: Stephan Kaminsky, Annie Preece-Scaringe

Our goal is to construct circuitry that can transmit battery power efficiently and create device that is able to control stopping distance of car. There are 3 phase of design: power transmission, control integration, and electronics packaging. The team will experience circuit and controller constructing and debugging as well as thermal and chassis management in electronics packaging. We are the nerve system of the ChemE car.

Mechanical

PROJECT LEAD: Lance Moll

TEAM: Lance Moll, Mace Grunsfeld, Ariel Plantz, Amanda Awan, Austin Lim, Radley Rigonan (not pictured)

Our main goal is to create a chassis thats small and light. We use CAD software, Solidworks, to design a chassis first that 3D print. We'll also be designing anything that the chemical teams need. Something that I want to try this semester, is having a type of liason with the chemical teams so that the chassis can work to what they require.

back to top