Power Teams

Magnesium-Air Battery

Project Managers: Rustam Gandhi & Hunter Ocker

Team Members:

|

Magnesium Air is a battery chemistry that utilizes a magnesium (or magnesium alloy) anode, an air cathode, and an aqueous electrolyte. Oxidization of magnesium at the anode and reduction of oxygen at the cathode form the overall product magnesium hydroxide. Previous work has investigated oxygen reduction catalysis at the cathode. This year, the focus will be on various easy-to-implement changes that will (hopefully) have a large impact on battery performance, followed by a focus on consistency to prepare for competition. |

Lead-Acid Battery

Project Manager: Carlos Ramirez & Daniela Paredes Robles

Team Members:

|

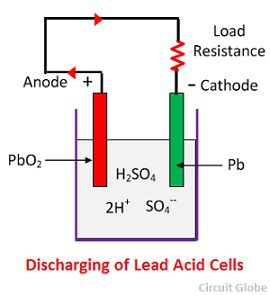

Lead acid batteries are a mature technology that has been applied to countless parts of our lives. The chemical energy in a lead-acid battery is stored in the potential difference between the two lead plates (PbSO4 and PbO2), and our electrolyte is Sulfuric Acid(H2SO4). This year, we hope to create a new iteration of last year’s battery that is focused on an increase in energy capacity, since in the past we have run into battery life issues. We are also focused on developing a new case design to safely contain all components of this battery, since lead and sulfuric acid are dangerous components that require proper care. With these improvements, we aim to be competition ready by the next WRC. |

Zinc-Air Battery

Project Managers: William Wei & Joshua Lee

Team Members:

|

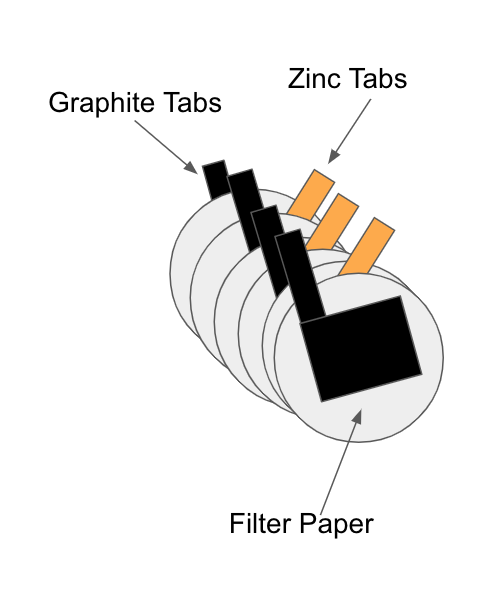

The Zinc-Air Battery team aims to utilize more sustainable battery chemistries to generate electric power for our cars. The components of the battery include a zinc anode, a carbon-based cathode that captures oxygen from air, and potassium hydroxide electrolyte. Our main goals for this year include researching and testing new improvements to our battery while focusing on calibration and consistency to excel at competition. We have been part of ChemE car for several years and have competed at both the regional and national competitions. |

Hydrogen Fuel Cell Battery

Project Managers: Prisha Davda & Arya Madan

Team Members:

|

Hydrogen Fuel Cells produce electricity with the combination of hydrogen and oxygen, and emit a singular byproduct - water. As a fairly new experimental team, we are currently researching and developing ways to improve and optimize catalyst activity and hydrogen production. Our aim for this year is to transition towards a Proton-Exchange Membrane fuel cell (PEMFC), while testing several cell designs with the goal of yielding consistent data. |

Control Teams

Vitamin C Clock

Project Manager: Inji Park & Richard Wetterer

Team Members:

Vitamin C Clock studies the reaction between ascorbic acid, iodide, and hydrogen peroxide. By manipulating concentrations of ascorbic acid, iodide, or hydrogen peroxide, the rate of our reaction and endpoint can be controllably altered. By detecting the abrupt change in color due to the starch indicator at the endpoint using a light sensor, the length of our reaction determines the duration of the car’s motion. Our goals are to continue developing a reliable calibration curve for use at competition. |

Electrochemical Clock

Project Manager: Jin Yu & Andrew Tran

Team Members:

The Electrochemical Clock team focuses on using principles of electrochemistry and electrochemical cells in order to power our clock. This year we will be focusing on designing a new mechanism based on horseradish peroxidase, an enzyme which is capable of producing a current through a series of redox reactions. Our goals with this new mechanism is to have a system that is more consistent to build and easier to manipulate, leading to a smoother and more reliable calibration curve. |

Enzymatic Clock

Project Manager: Alaa Alkhamis & Katharine Coda

Team Members: Fall:

|

The enzymatic clock team utilizes the breakdown of hydrogen peroxide into oxygen and water catalyzed by the enzyme catalase. As oxygen gas is formed, it pushes a black guar gum solution through a tube until it reaches a photosensor, which stops the car when the guar gum solution blocks the light. Our goal is to create a reliable calibration curve by getting our reaction more consistent week-to-week." |

Chassis Teams

Electrical

Project Managers: Aaron Lee

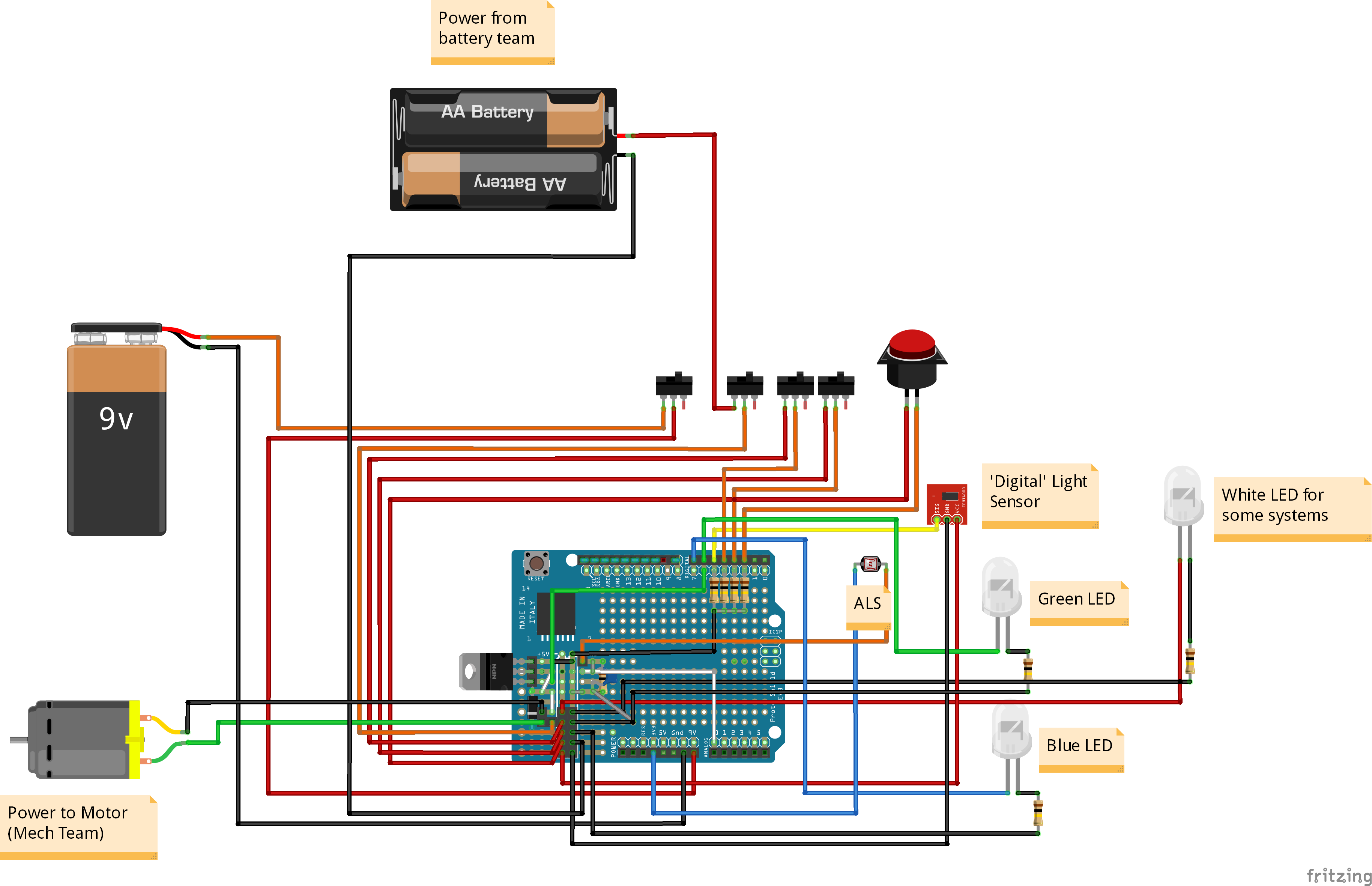

Team Members:

|

The electrical team devises ways of converting the Control Teams’ data into voltages so that we can determine whether the car should be running or not. Using this data, we turn on and off the power supplied by the Power & Battery Teams to the motor. We have worked to increase data collection for different teams by measuring power from the battery and measuring times it takes to go a certain distance so we can calculate a more accurate velocity. Currently, we working on making a more reliable mechanism to stop giving the car power and making it stop. |